▌ Meta-Air Batteries

|

The aprotic Li−air battery consisted of a porous O2 diffusion cathode, a metal Li anode, and an organic Li+ conducting electrolyte possesses a theoretical energy density of ∼3600 Wh/kg, which is far transcends those of today’s available battery systems, especially the widely used Li-ion batteries, and thus has been recognized as a most promising post Li-ion battery technology. Despite being promising, the research in this direction is at a very early stage. The development of the cell components that can withstand the harder operation conditions to enable the long-term operation of Li-air batteries is what we want to do. |

▌ Electrosynthesis and Electrocatalysis

|

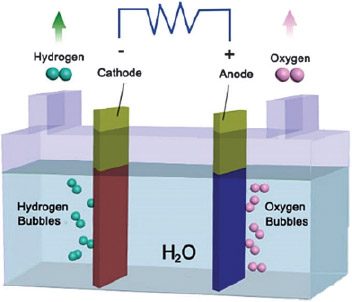

With increasing energy demand and impending climate change, significant concerns have been raised over the security of energy. Electrochemical conversion processes that could convert molecules in the atmosphere (e.g., water, carbon dioxide, and nitrogen) into higher-value products (e.g., hydrogen, hydrocarbons, oxygenates, and ammonia) by coupling with renewable energy would be good choices. However, electrocatalysts play a key role in these energy conversion technologies because they could increase the rate, efficiency, and selectivity of the chemical transformations involved. The grand challenge is to develop high-performance advanced electrocatalysts to enable the widespread use of clean energy technologies. |

|

▌ New types of ion batteries

|

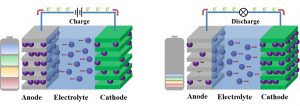

The operation mechanisms of new types of ion batteries, like Na-ion and K-ion batteries, present in a rocking-chair fashion, similar to that of Li-ion batteries, that is, charge carries migrate between the cathode and anode to achieve energy storage/release. The life of the battery depends on the reversibility of the electrode material during the cycling. Therefore, it is very important to understand the storage mechanism of ions in the materials and develop stable electrode materials with long cycle life. |

▌ Solid Oxide Electrolysis Cell

|

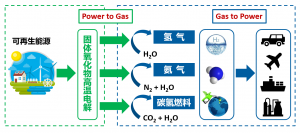

The solid oxide electrolysis cell (SOEC) utilizes electric energy and industrial waste heat to realize high-temperature electrolysis to produce “green hydrogen”, “green ammonia” and “syngas”, and the electrolysis efficiency is close to 100%. It is one of the key technical routes to achieve the “dual carbon” goal and establish an integrated energy system.

|

|